Trade Members Get 10% Off. Sign Up Today

A Guide to Recessed Strip Lighting

Recessed strip lighting is one of the most effective ways to achieve a clean, integrated LED installation.

By embedding the strip within a channel or profile, only the light output is visible, creating a professional finish while protecting the strip from damage.

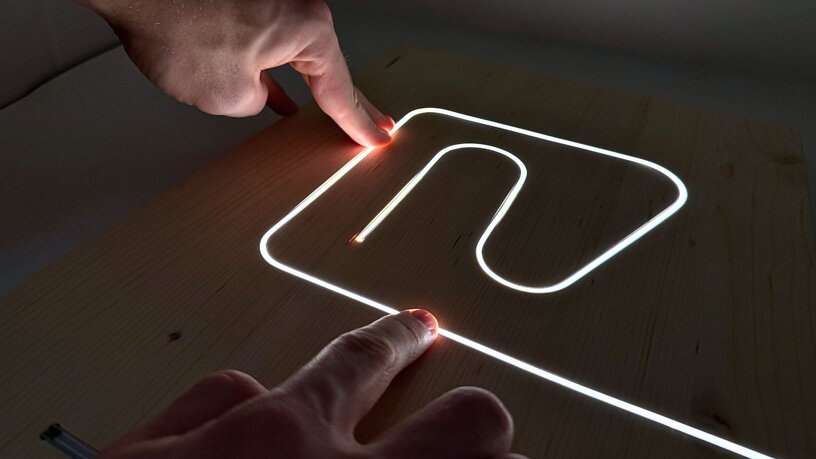

While this remains the standard method for achieving a seamless effect, many joinery projects now use routed LED Neon Flex. With its built-in heat sink and diffuser, Neon can reduce installation time and simplify recessing for continuous lighting runs.

This guide outlines recessed lighting, its applications, and how Ultra LEDs’ range supports precise and durable installation.

What Is Recessed Strip Lighting?

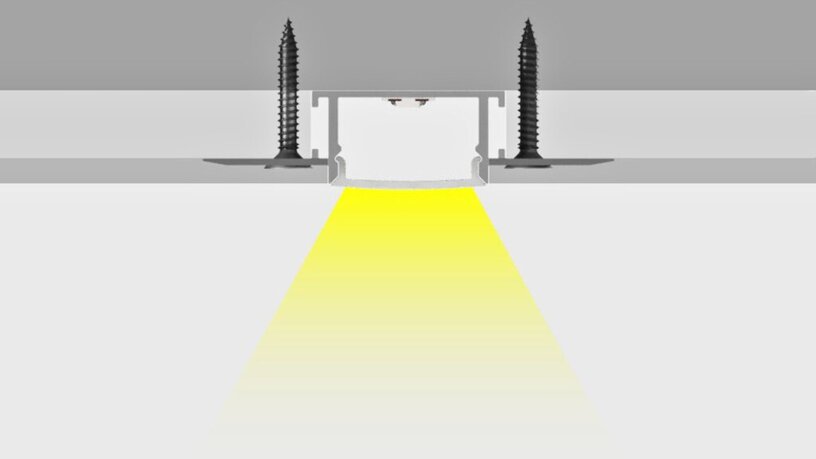

In recessed applications, LED strips are installed into a cut-out or channel within furniture, ceilings, or walls. A diffuser is fitted over the strip to create a uniform finish and reduce glare.

Although this remains the standard approach, many joinery projects now use routed LED Neon Flex. Its built-in heat sink and diffuser reduce installation time and simplify recessing in detailed joinery work.

Recessed lighting is common in:

• Joinery and cabinetry (for under-shelf or display illumination)

• Ceiling troughs or coves (for architectural detail lighting)

• Retail and commercial displays (for concealed product highlighting)

• Wall niches and corridors (for visual depth and low-level guidance)

This method ensures controlled illumination while keeping the light source hidden and protected.

A Step-by-Step Guide to Recessed Lighting Installation

Plan the Layout

- Determine where the light will be recessed and select the appropriate profile type for depth, width, and material compatibility.

Prepare the Recess

- Cut or route a channel in the desired surface, ensuring it matches the external dimensions of the profile.

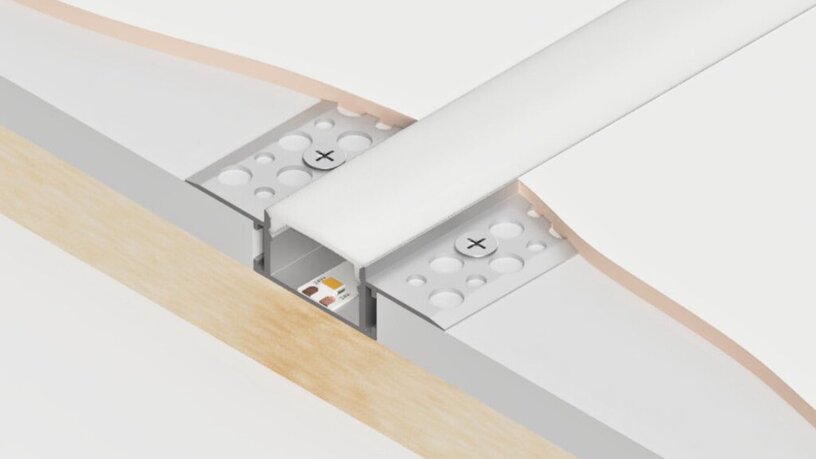

Fit the Profile

- Secure the aluminium channel using mounting clips, adhesive, or screws depending on surface type.

Install the LED Strip

- Clean the channel, then apply the strip, ensuring the adhesive backing is fully bonded and no tension is applied.

Attach the Diffuser

- Snap or slide the diffuser into place to create a continuous, even output line.

Connect Power and Test

- Wire the strip to a suitable 24V driver, check polarity, and test before final fitting.

Choosing the Right Product

Selecting the correct product depends on the installation type. Recessed applications vary in depth, and this determines which LED strip or profile is most suitable.

A shallow recess benefits from higher LED density or COB tape for uniform output, while deeper channels can accommodate standard-density tapes such as 60 LEDs per metre.

Here are a few examples:

Micro 3 Neon Flex

Unlike standard strip lighting, Neon Flex can be recessed directly into a cut groove without requiring an aluminium profile.

Ultra LEDs’ Micro 3 Neon Flex (3×6 mm) is designed for joinery and cabinetry where space is limited. Its compact design provides uniform, diffused light within shallow recesses such as shelving, wardrobes, and display units.

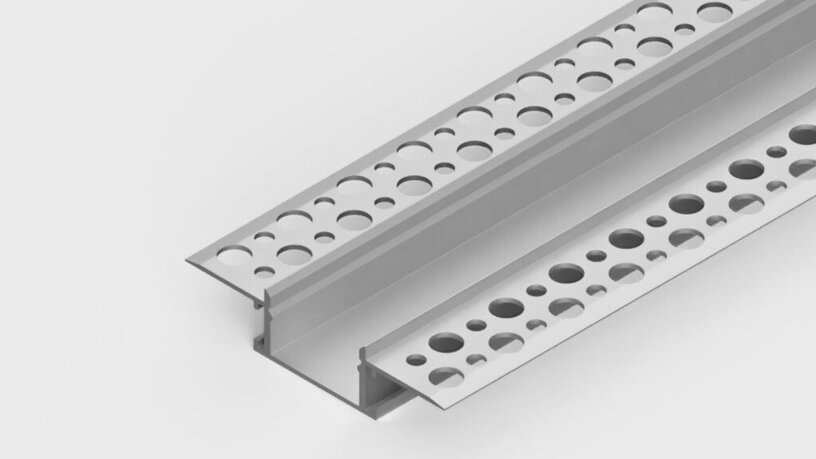

Recessed Aluminium Profiles

For larger or architectural installations, aluminium profiles provide structural housing and diffusion control.

Options include:

- Slimline Profiles: For shallow recesses or compact joinery.

- Plaster-In Profiles: For seamless integration within ceilings and walls.

- Deep Profiles: For achieving full diffusion and reducing glare in visible installations.

Benefits of Recessed Lighting

Protection:

When installed within an aluminium profile, LED strips are protected from dust, impact, and general handling. The profile also provides heat dissipation, which supports long-term reliability and performance.

Appearance:

Recessed profiles create a flush, built-in lighting effect. Visibility of the diodes depends on the LED tape and diffuser used, but the overall look remains integrated and consistent.

Integration:

Suitable for ceilings, furniture, and joinery where the lighting must appear part of the structure rather than surface-mounted.

Performance:

Profiles improve thermal management and help maintain consistent light output across longer runs.

Versatility:

Can be used in residential, commercial, and retail environments, offering flexibility across joinery, display, and architectural lighting applications.

Installation Considerations

Depth and Width:

- Ensure the recess depth and width are suitable for the chosen strip or profile. This allows for full diffusion without visible hotspots and ensures a snug fit within the housing.

Heat Management:

- Aluminium profiles dissipate heat effectively, maintaining LED performance and extending lifespan.

Diffuser Selection:

- Clear diffusers increase light output, while frosted options provide softer, more uniform illumination.

Tools:

- Recesses are typically cut using a router or saw. Fixing clips or adhesive can then be used to secure the profiles in place.

Recessed strip lighting offers a clean, integrated finish suitable for joinery, retail, and architectural applications.

The depth and layout of each recess determine the most appropriate LED strip, profile, and diffuser combination.

Selecting the right configuration ensures even light distribution, heat management, and long-term reliability.

With Ultra LEDs’ range of recessed profiles, Neon Flex, and compatible accessories, installers can achieve consistent, professional results across any project.

FAQs – Recessed Strip Lighting

What is recessed LED strip lighting?

Recessed LED strip lighting is installed into a channel or cut-out so the tape sits flush with the surface. This creates a clean, built-in appearance with only the light output visible.

Do recessed LED strips need aluminium profiles?

Aluminium profiles are recommended for recessed LED strips to provide heat dissipation, protection, and structural support. Some flexible options, such as LED Neon Flex, can be recessed directly into a groove without a profile.

How deep should a recess be for LED strip lighting?

Recess depth depends on the LED type and profile. Shallow recesses suit COB or high-density strips for smooth diffusion, while deeper channels allow standard-density tape and improved glare control.

Can recessed LED lighting be dimmed?

Recessed LED lighting can be dimmed using a compatible 24 V driver and control method such as DALI, 0–10 V, RF, or DMX.

Which diffuser is best for recessed LED profiles?

A frosted or opal diffuser provides the most uniform light output and reduces diode visibility. Clear diffusers offer higher brightness but may expose hotspots.

Where can recessed LED strips be installed?

Recessed LED strips can be fitted into ceilings, walls, cabinetry, shelving, and display units for integrated lighting in residential, retail, and commercial environments.

Do recessed LED strips get hot?

Aluminium profiles act as heat sinks, allowing recessed LED strips to operate efficiently without overheating or affecting performance.

Get in touch with Ultra LEDs today

Planning your next lighting install? Explore Ultra LEDs’ full range of drivers, LED strips, and accessories — built to deliver reliable, professional results across commercial and display projects.