Trade Members Get 10% Off. Sign Up Today

Understanding Voltage Drop In LED Installations

If LED strips are dim at the far end of a run or colours shift unexpectedly, voltage drop is usually the cause. As current moves through the circuit, resistance increases, reducing voltage and affecting performance over distance.

In longer runs or high-load systems, this can lead to brightness loss, colour shift, flicker, or full failure in sections furthest from the power supply.

This guide explains what causes voltage drop, how to spot it in real installations, and how to prevent it — covering cable gauge, voltage selection, power injection, and layout design.

What Is Voltage Drop In LED Lighting?

Voltage drop occurs when resistance in the circuit, typically from cables, connectors or PCB traces, causes voltage to decrease as current travels away from the power source.

In an LED strip, this means the LEDs furthest from the power supply receive less voltage than those at the start of the run. When that voltage falls below the required operating level, it leads to visible performance issues.

Signs Of Voltage Drop In LED Installations

- Dimming LEDs – LEDs at the end of the run appear dimmer than those closer to the power supply.

- Uneven brightness – Gradual fading or inconsistent illumination across the strip.

- Colour shifting – Particularly in RGB and tunable white LEDs, where insufficient voltage affects colour accuracy.

- Power loss over distance – A visible drop in performance when LED strip length increases beyond recommended limits.

What Causes Voltage Drop in LEDs?

Voltage drop occurs due to a combination of circuit resistance and insufficient power delivery. Key contributing factors include:

1. Cable Resistance and Wire Gauge

Electrical resistance increases with cable length, reducing the voltage reaching the LEDs. Thin wires (higher gauge numbers) have more resistance, leading to greater voltage loss.

Solution: Use lower gauge (thicker) wires to minimise resistance, especially for longer runs.

2. Excessive LED Strip Length

Longer LED strip runs accumulate resistance, reducing voltage delivery and affecting brightness.

Solution: Use power injection points based on the product specification. This could be every 2.5m, 5m or even 15m depending on the strip type. For long runs, also consider dividing the circuit into smaller segments, each powered directly.

3. Poor-Quality Connectors and Solder Joints

Low-quality connectors create additional resistance, contributing to voltage drop.

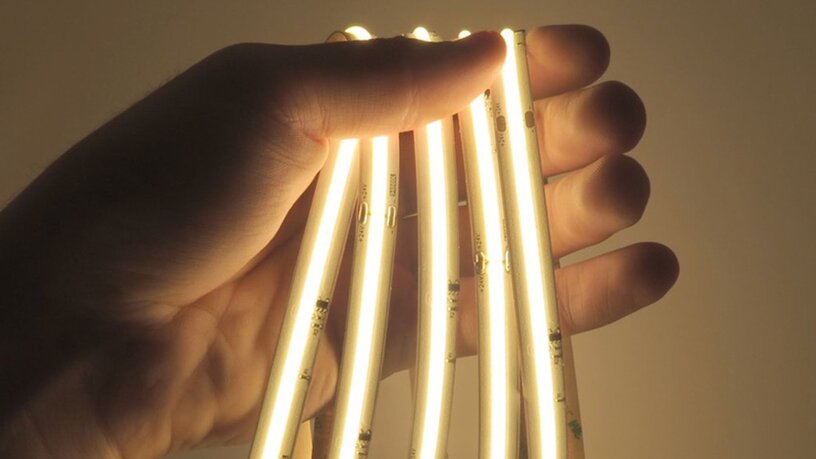

Solution: Choose LED strips with heavier copper weight PCBs to reduce internal resistance and maintain voltage stability.

4. High-Resistance PCB Designs

Some LED strips have narrower or thinner PCB traces, leading to higher internal resistance. This can make voltage drop more severe, even on shorter runs.

Solution: Choose high-quality LED strips with heavier weight PCB traces to improve current flow.

5. Temperature Effects on Conductivity

High temperatures increase electrical resistance, worsening voltage drop in installations with poor heat dissipation.

Solution: Ensure adequate ventilation and use heat-resistant wiring where necessary.

How Voltage Drop Affects LED Performance

Voltage drop doesn’t just reduce output; it also affects whether the system performs as intended.

Reduced Brightness: Strips furthest from the driver underperform.

-

Colour Inaccuracy: RGB and CCT strips may shift tone or hue.

-

Instability: Flickering or drop-out in low-voltage sections.

Note: Voltage drop does not reduce LED lifespan. In fact, slightly lower voltage may extend lifespan due to reduced heat output.

How To Prevent And Fix Voltage Drop In LED Installations

1. Choose the Right LED Strip Voltage

24V LED strips experience significantly less voltage drop than 12V alternatives, making them a reliable choice for longer runs. For even greater efficiency across extended distances, 48V systems are even better suited due to reduced current draw and improved voltage stability.

2. Use Thicker Cables for Reduced Resistance

Lower gauge (thicker) wires reduce resistance and maintain voltage stability over longer distances.

3. Implement Power Injection for Longer Runs

Power injection helps maintain consistent voltage across longer runs by delivering power at multiple points. The spacing between injection points depends on the product — for example, some 2.5m LED strips require injection every 2.5m, while others only need it every 15m. Always check the specification for injection intervals.

Where appropriate, wire LED strips in parallel instead of series to ensure consistent voltage across each section.

4. Use Quality LED Connectors and Soldered Joints

High-quality soldered connections or premium LED connectors prevent unnecessary resistance.

Avoid daisy-chaining multiple connectors, as each additional joint increases resistance.

How to Calculate Voltage Drop

Voltage drop can be estimated using:

Voltage Drop (V) = (2 × Cable Length × Current × Resistance) / 1000

Where:

- Cable Length = total run (in metres)

- Current = amperage drawn by the LEDs

- Resistance = ohms per kilometre, based on cable gauge

Aim for less than 5% voltage drop across the run. Anything above that may require power injection or thicker cable.

Voltage drop can occur in both the cable and the LED strip itself. Cable voltage drop is often more severe — especially over long distances — but both contribute to the final voltage seen by the LEDs.

What Does 5% Voltage Drop Look Like?

A 5% drop on a 24V system equals a loss of 1.2V by the end of the run. This can cause:

Mild dimming in single-colour strips

Noticeable hue shift in RGB or tunable white

Poor dimming behaviour under low brightness settings

In commercial environments or camera-sensitive installations, even this level of drop can impact the end result.

Differentiating Voltage Drop In Cable Vs Strip

Voltage drop can occur in both the cabling and the LED strip — and while they're related, each has its own causes and effects.

- Cable voltage drop is often the greater contributor, especially in long-distance runs between the driver and the start of the strip. Resistance in the cable causes voltage to fall before it even reaches the LEDs, particularly if the wire is undersized or the current is high.

- Strip voltage drop happens along the internal PCB traces of the LED strip. It accumulates as current travels further along the strip, especially on lower copper-weight PCBs.

Both types of voltage drop contribute to total performance loss. To minimise issues, cable runs should be kept short, wire gauge should be sufficient, and power injection points should be spaced according to specification.

FAQs

What is an acceptable voltage drop in an LED installation?

A drop of up to 5% is generally acceptable. Anything beyond this can cause visible dimming and require corrective measures.

How do I calculate voltage drop in my setup?

Use the voltage drop formula provided earlier or an online voltage drop calculator to determine the optimal wire thickness and power supply requirements.

Can I use a higher voltage power supply to fix voltage drop?

No, exceeding the rated voltage can damage LEDs. Instead, opt for power injection or select a higher voltage-rated LED strip (e.g., 24V instead of 12V).

Never exceed the rated voltage of the LED strip. This will damage the components

Why is voltage drop more noticeable in longer LED runs?

Longer runs have increased resistance, leading to greater voltage loss. This is why shorter runs or higher voltage strips (24V+) are recommended.

What’s the difference between power injection and using a larger power supply?

Power injection delivers voltage at multiple points, whereas a larger power supply only increases total available power without addressing voltage stability along the LED strip.

Get in touch with Ultra LEDs today

If you've decided on the LED strips for your next installation — or need help selecting the right voltage, cable, or injection setup — our team can guide you through the best options to avoid voltage drop and ensure consistent performance.