Trade Members Get 10% Off. Sign Up Today

What Is LED Binning?

Consistent lighting is essential in professional installations. On long runs, curved features, or mirrored surfaces, even subtle differences in brightness or colour temperature can disrupt the overall effect.

LED binning helps avoid this by grouping diodes that perform within tightly defined parameters, ensuring uniform output across strips and fittings. For lighting designers and specifiers, it’s a critical step in delivering cohesive, high-performance results.

LED Binning Explained

This section will delve into how LEDs are manufactured, the terminology used to describe binning precision, and how these factors ensure top-quality lighting products.

How LEDs are manufactured

Despite the advanced technology behind LED production, natural variations in manufacturing are inevitable. As such, no two LEDs are exactly alike - even within the same production batch, LEDs inherently develop slight variations in their light-emitting properties.

To address these variations, manufacturers implement a critical sorting process where each LED undergoes testing for:

- CCT (Correlated Colour Temperature) - The specific shade of white light (measured in Kelvin)

- Luminous output - The total light produced by each diode

- Forward voltage - A measure of how much power the LED uses when it’s turned on

- CRI (Colour Rendering Index) - A measure of how natural colours look under the LED light

By sorting these LEDs into "bins" with matching performance characteristics, manufacturers ensure consistent and uniform lighting across strips, modules, and fixtures.

Binning Terminology

The lighting industry uses several specialised terms to describe binning precision:

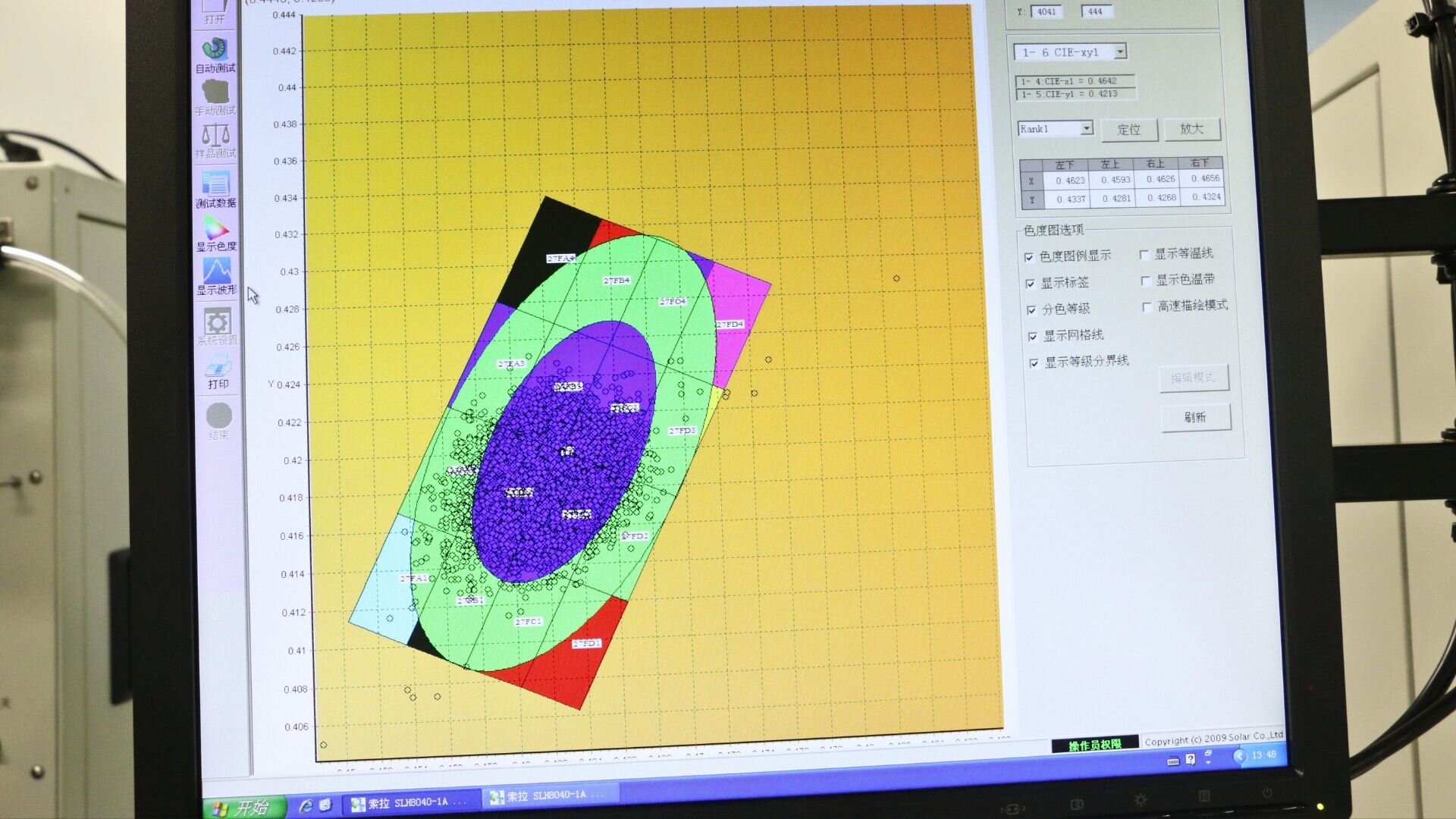

- MacAdam Ellipses: These visually represent colour differences, with fewer steps (typically ranging from 1 to 7) indicating a smaller tolerance for variation. A 1-step ellipse reflects extremely tight control (and is rarely achieved in practice), while a 3-step ellipse is generally indistinguishable to the human eye. Higher steps, such as 5, begin to show more noticeable shifts in colour.

- CCT Tolerance: CCT refers to the appearance of white light, expressed in Kelvin (K), i.e. warm white at 2700K or cool white at 5000K. CCT tolerance is the acceptable deviation from this target. A CCT of 3000K with ±100K tolerance means the actual output could range from 2900K to 3100K and still be considered compliant with the specification - although at this colour temperature, that difference would be very noticeable.

- ANSI Standards: These define industry-accepted binning ranges to ensure LEDs meet specific colour criteria. Since CCT alone doesn’t fully capture all colour nuances, especially subtle tint shifts, DuV (Delta u,v) is commonly used alongside it to refine the measurement of colour tolerance.

Why Binning Matters In Real-World Installs

This section will explore how proper binning affects visual uniformity across reels, design consistency over time, and the difference between budget and professional products.

Visual Uniformity Across Reels

In large-scale installations requiring multiple runs of LED tape lights, such as perimeter hallway lighting or accent lighting across multi-storey architectural features, inconsistencies in binning can become immediately apparent.

Even if products share the same 3000K specification on paper, slight differences in colour temperature can appear once installed, affecting the visual consistency and overall appearance of the final design. LED colour consistency becomes particularly critical in:

- Open-plan areas where multiple LED strips are visible in the same line of sight

- Lighting applications where strips run parallel to each other

- Curved joinery where the eye naturally compares adjacent sections

- High-end architectural lighting, where clean, uniform output is crucial to the final effect

Design Consistency Across Phased Projects

In commercial projects (retail chains or corporate offices), lighting is often installed in phases over months or even years. If binning isn't carefully managed:

- Different store locations can have uneven brand lighting

- Office floors completed at separate times could show visible lighting inconsistencies

- Replacement sections may not match the original installations

These variations can cause maintenance problems and affect the overall quality of the lighting design, making investing in professional lighting design essential for long-term consistency.

Budget Vs. Professional Products

LED strip lights are available at a wide range of price points, but lower-cost options often compromise on binning precision. Budget LED tape typically comes from broader or mixed bin ranges, resulting in wider tolerances and more uneven output.

At Ultra LEDs, we’ve seen numerous cases where customers initially chose cheaper strips, only to face visible mismatches after installation - such as uneven red tones across the same ceiling, even though the products shared the same spec on paper.

In most cases, resolving these inconsistencies requires a full replacement with properly binned alternatives - a costly fix that could have been avoided by choosing professional-grade LED tape from the outset. Higher-end product ranges minimise this risk with tight binning LED strips and more rigorous manufacturing controls.

How Ultra LEDs Approaches Binning

At Ultra LEDs, we’ve built our LED binning process around the needs of professional lighting projects - where consistency isn’t a bonus, it’s a requirement. Rather than relying solely on standard manufacturing tolerances, we’ve put a more rigorous strategy in place:

- Direct supplier collaboration: We work closely with manufacturers to ensure bin consistency across entire orders, not just individual batches.

- “One-bin-only” policy: For our professional-grade ranges, we specify strict single-bin selection - meaning every strip within a product line offers visually uniform output.

- Proactive quality checks: Our in-house testing and quality control teams actively screen for binning discrepancies early, preventing mismatched output on-site and reducing the risk of costly replacements.

This comprehensive approach allows Ultra LEDs to confidently supply professional LED tape colour matching for projects that require precise colour accuracy, including:

- High-end retail environments where consistent brand lighting is critical

- Hospitality spaces where ambience directly impacts guest experience

- Museum and gallery lighting where accurate colour rendition is essential

- Long runs of linear lighting where even minor shifts in hue can become distracting

For these demanding applications, our DALI constant voltage drivers and dimmable constant voltage drivers provide the perfect complement to our tightly-binned LEDs, offering precise control that preserves colour integrity even at lower brightness levels.

FAQs

What is a MacAdam Ellipse?

A MacAdam Ellipse describes how noticeable a colour difference is to the human eye. The range goes from 1 to 7 steps, with a 1-step ellipse showing minimal variation that’s nearly impossible to detect. A 3-step ellipse represents differences that are generally not visible, while a 7-step ellipse allows for much more noticeable shifts in colour.

Are all Ultra LEDs’ products tightly binned?

No, only our high-end ranges come with guaranteed precise binning. Our entry-level options might have broader tolerance limits and allow for more variation.

Can I mix LED strips from different batches?

Strips should only be mixed if they come from the same bin. Even when they share the same CCT (like 3000K), discrepancies in colour can still be noticeable across different batches if the bins aren't matched.

When does binning matter most?

Binning is most critical when all LEDs are visible together - such as in retail displays, ceiling runs, signage, or joinery. For isolated applications (like a single strip per room), small variations may go unnoticed.

How do I know what bin I’m getting?

Ultra LEDs can provide binning details upon request. Simply let us know the project needs, and we’ll help with binning accuracy and ensuring a consistent LED supply throughout the process.

Planning a large linear installation or working on a brand-specific, high-end lighting project? Discover Ultra LEDs’ range of expertly binned LED strips and modules, including our single colour constant voltage LED tape, selected to ensure consistent colour quality and flawless uniformity across every reel - even in the most intricate applications. Contact our team today, or take a look at our FAQ for more information.

Get in touch with UltraLEDs today

Need support choosing between constant voltage and constant current for your next installation? Ultra LEDs supplies the LED strips, drivers, and control systems needed to deliver reliable performance in both flexible and fixed-output systems.