Trade Members Get 10% Off. Sign Up Today

Flexible LED Installations: Bending & Mounting LED Strips | UltraLEDs

When installing LED strips, navigating bends and curved surfaces can be a challenge. Without the right approach, improper bending can strain circuits, cause uneven illumination, and impact long-term performance.

For projects requiring curved lighting, selecting the right solution is key. Flexible options like LED Neon Flex and Bendable Double Row Tape adapt to curved surfaces while maintaining consistent light output. Understanding how these solutions work ensures reliable performance and a clean, professional installation.

In this guide, we explore bending LED strips effectively, the best lighting solutions for curved installations, understanding bending capabilities, and what to consider to ensure your project delivers long-lasting performance.

Understanding LED Flexibility & Bending Capabilities

Flexible LED solutions aren’t all designed to bend in the same way — each product has different flexing capabilities depending on its circuit board design, construction, and intended application.

While some LED strips can handle curves with ease, others require specific installation methods to maintain performance and prevent damage.

Before planning an installation, it’s important to understand the flexibility of different LED solutions, how their PCB structure affects bending limitations, and what factors impact long-term reliability. Choosing the right product ensures uniform illumination, stable electrical connections, and a professional finish.

How LED Strips Bend: Key Technical Considerations

Understanding how LED strips bend is essential for selecting the right product for your installation. Factors such as PCB structure, bend direction, and bend radius determine how well an LED strip can adapt to curves, corners, and flexible layouts without compromising performance or durability.

PCB Structure & Circuit Design

A Printed Circuit Board (PCB) is the core component of an LED strip, responsible for conducting electricity and providing structural integrity. Its design directly affects the strip’s flexibility, durability, and overall performance in an installation.

How PCB Design Affects Flexibility

The flexibility of an LED strip is determined by its PCB design, which dictates how the strip can bend without compromising electrical connections.

- Standard PCBs: Designed for linear or gently curved applications, these bend only in the vertical direction (up and down). Excessive bending beyond the recommended radius can strain solder joints, leading to flickering or circuit failure.

- Specialist PCBs: Some flexible LED strips feature a PCB construction that allows for controlled horizontal bending along their length, enabling side-to-side flexibility without damaging electrical connections.

Understanding the bending limitations of standard and specialist PCBs ensures the right product selection for an installation, minimising circuit stress and maintaining uniform illumination.

Bend Direction: Vertical vs. Horizontal

Standard LED strips are designed to bend in a single direction — following the correct bend axis is essential to prevent circuit strain, solder joint failure, and uneven lighting.

- Vertical bending (up and down): Most standard LED strips flex in this direction, making them suitable for surface-mounted lighting, under-cabinet installations, and indirect backlighting. However, excessive bending beyond the recommended radius can cause circuit strain and performance issues.

- Horizontal bending (side to side): Standard LED strips cannot bend laterally without damaging internal components. LED Neon Flex solutions offer horizontal, vertical, or dual-bend flexibility, making them ideal for curved architectural features, signage, and installations requiring smooth contouring.

- Dual Bend Flexibility: Some options in our Professional Neon Flex range, such as 16x16 and 10x10 Dual Bend Neon Flex, offer both vertical and horizontal bending for seamless shapes and installations. These solutions reduce the need for multiple lighting products or connectors in projects requiring smooth, continuous curves.

Bend Radius & Installation Limits

Every LED strip has a minimum bend radius—exceeding this can cause electrical failure, dark spots, or performance issues over time.

Why it matters: Ignoring the bend radius puts strain on the circuit, weakens solder joints, and leads to uneven lighting.

Standard LED strips: Should always follow the manufacturer’s bend radius guidelines to prevent damage.

Neon Flex & Bendable LED Tape: A highly flexible option for LED installations, maintaining uniform lighting without compromising flexibility.

Choosing the Right LED Lighting Solution for Curved & Flexible Installations

Selecting the right lighting solution depends on the specific requirements of a project. If an installation requires a simple 90-degree transition, corner connectors may be the best option.

However, if your project involves bending around corners or integrating LED strips into curved spaces, the solutions below offer the flexibility needed for seamless, professional results.

You can read more on how to install led strips around corners here.

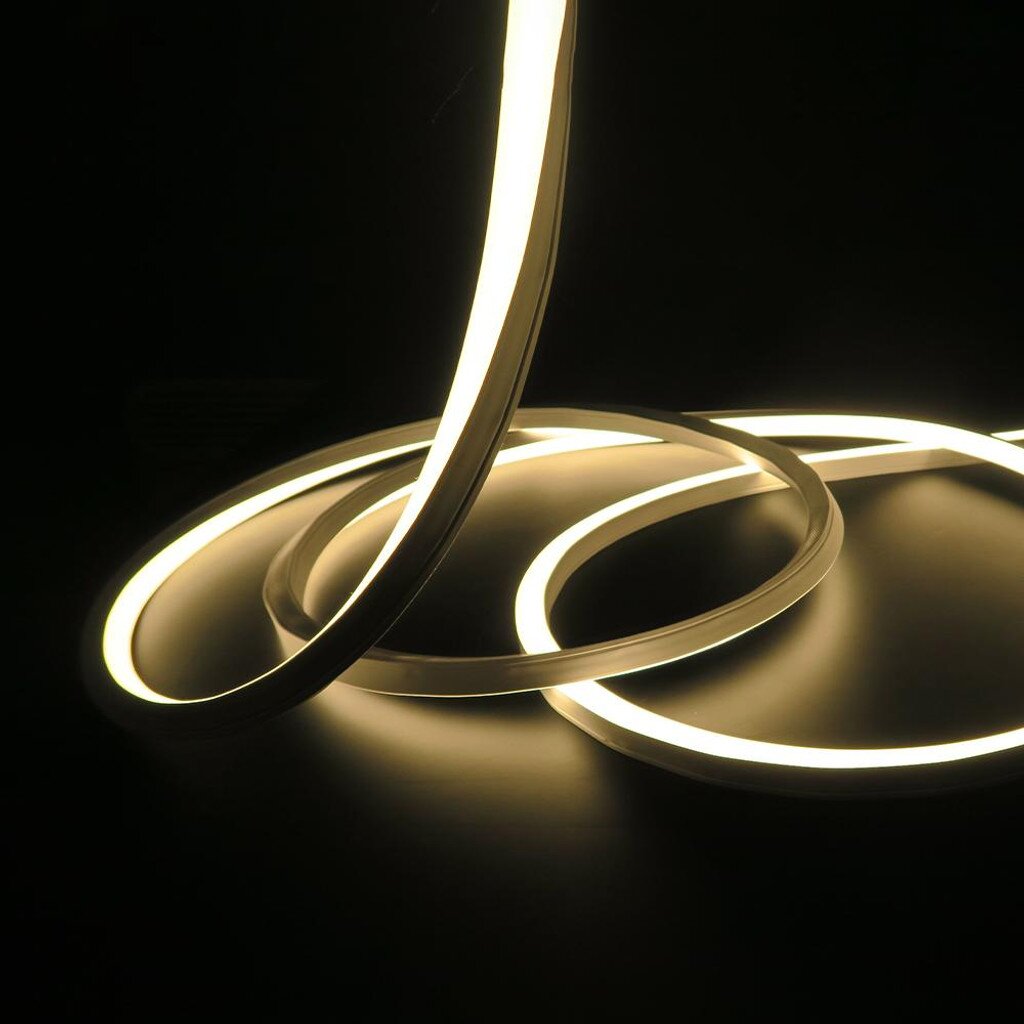

LED Neon Flex

Best for: Architectural curves, furniture, cabinetry, and, signage.

Neon Flex provides uniform, dot-free illumination with smooth multi-directional bending. Its durable silicone housing ensures longevity, making it ideal for professional installations requiring flexibility and a seamless finish.

Bendable Double Row LED Tape

Best for: Large-scale curved applications requiring high brightness.

Designed for expansive installations, the Bendable Double Row Tape features increased LED density for bright, consistent illumination while maintaining flexibility.

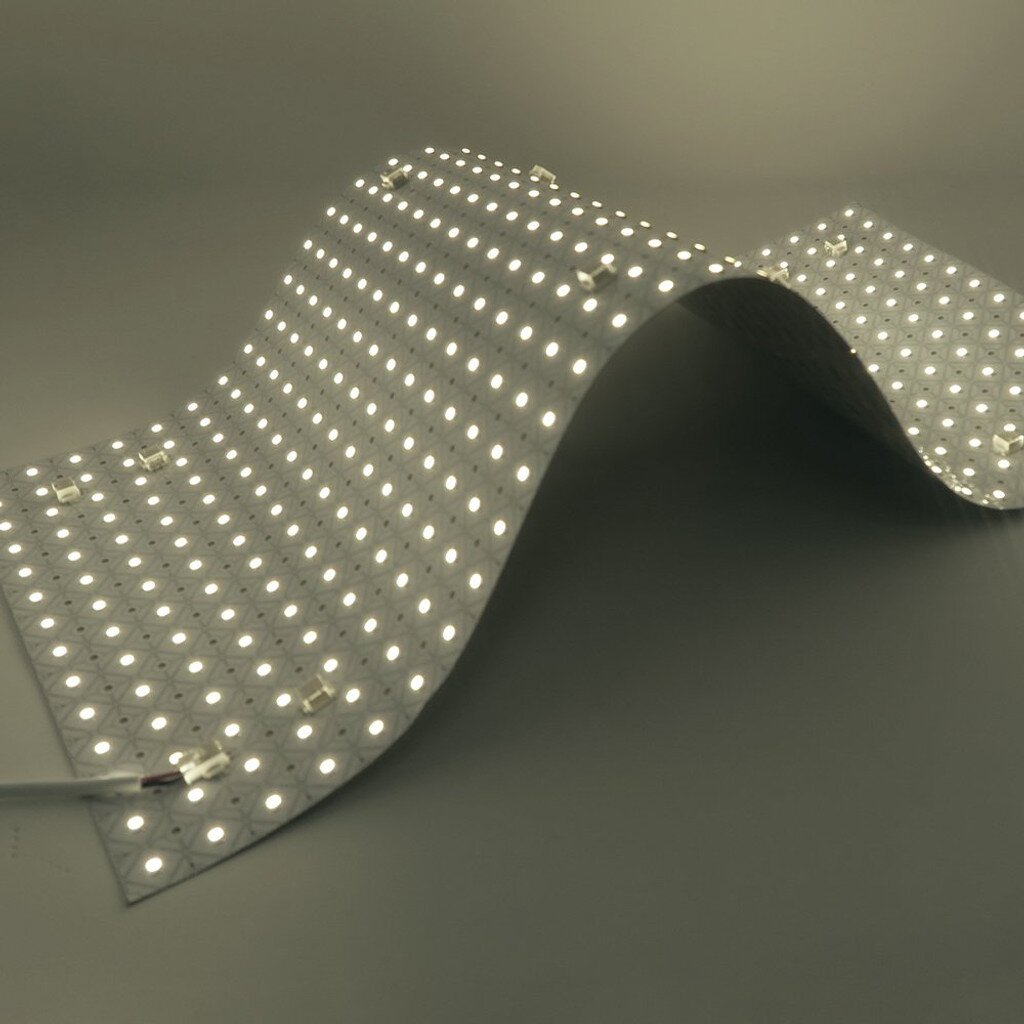

LED Light Sheets

Best for: Backlighting applications, curved furniture, and retail displays.

LED Light Sheets provide seamless, even illumination for curved surfaces and intricate layouts. Their ultra-thin profile and flexible cut points make them ideal for integrating into signage, architectural features, and retail displays.

Bendable Plaster-In Profiles

Best for: Integrated architectural lighting and recessed curved designs.

Designed for recessed installations, these profiles allow flexible LED strips to follow curves while maintaining a structured, professional finish.

Best Practices For Bending LED Lighting

To ensure a stable and reliable installation, follow these key practices when working with flexible LED strips:

Follow the Bend Radius Guidelines – Exceeding the recommended bend radius can strain circuits, weaken solder joints, and create uneven lighting. Always check product specifications before installation.

Secure with Mounting Channels – Prevent movement and maintain stability by using bendable plaster-in profiles or flexible mounting tracks, ensuring a clean, professional finish.

Minimise Handling During Installation – Excessive bending or repositioning can weaken internal connections. Where frequent movement is required, opt for LED Neon Flex or bendable LED tapes designed for flexible applications.

Common Mistakes to Avoid

Avoiding common installation errors will help maintain longevity and performance:

- Forcing a bend beyond the strip’s limit – Can cause circuit stress or break the LED connections.

- Bending across the wrong axis – Not all LED strips can bend horizontally; ensure the correct product is selected.

- Skipping structural support – Mounting channels or diffusers help maintain positioning in curved applications.

- Overlooking power supply requirements – Longer LED runs need appropriate power injection to prevent dimming.

FAQs

Can all LED strips bend?

No, only flexible LED strips are designed for bending. Standard LED tapes are not built for curved installations and may be damaged if forced into a bend beyond their design limits.

Can you bend LED strip lights around corners?

Yes, but we recommend using LED corner connectors, as bending standard LED strips at sharp angles can cause circuit damage. The right connector depends on the type of corner—read more in our blog [link].

How do I ensure even brightness across a curved installation?

Use high-density LED strips to reduce light gaps, ensure correct power supply distribution, and securely mount strips using appropriate profiles or tracks to maintain uniform illumination.

Can LED strips be installed in tight curves?

Yes, all LED strips offer some level of flexibility. Most standard LED strips are designed to bend in a vertical direction, while specialist options — such as horizontal bend or dual bend LED strips — provide greater versatility for complex installations.

For a smoother setup, plan installations to align with a strip’s natural bending direction. Standard LED strips naturally bend vertically, so designing around this can simplify the installation and reduce the need for specialist bendable strips.

Ready to find the right solution for your next installation? Browse our corner connectors for seamless corner installations, or explore our LED strip lighting solutions to complete your setup.

Get in touch with Ultra LEDs today

Whether you're working with bends, curved spaces, or 90-degree corners, Ultra LEDs has the right lighting solution for your project. Our team of experts can provide guidance and high-quality products to help you achieve seamless installations.