Trade Members Get 10% Off. Sign Up Today

How To Cut LED Strip Lights

Can you cut LED strip lights without damaging them? Yes - when done correctly. Cutting LED strips requires the right approach.

If not done properly, there’s a risk of damaging the PCB, which can lead to failure across part or all of the strip. Understanding how and where to cut prevents these issues and ensures smooth, long-lasting illumination.

This guide covers the essential steps for cutting LED strips correctly, explains why accuracy is important, and provides expert insights to ensure that LED strip lights remain working at their best.

Need a visual guide? Watch our YouTube video for a step-by-step installation walkthrough here.

Why Cutting LED Strips Correctly Matters

Cutting LED strip lights isn’t just about adjusting length — incorrect cuts can break the circuit, leaving sections unlit. Each strip consists of small LED chips mounted on a flexible PCB, with LEDs spaced just millimetres apart to ensure seamless illumination.

Damaging the circuit can break the connection, causing sections of the strip to stop working. Making clean cuts at the correct points ensures the strip functions properly and maintains consistent lighting.

Understanding Cut Points On LED Strips

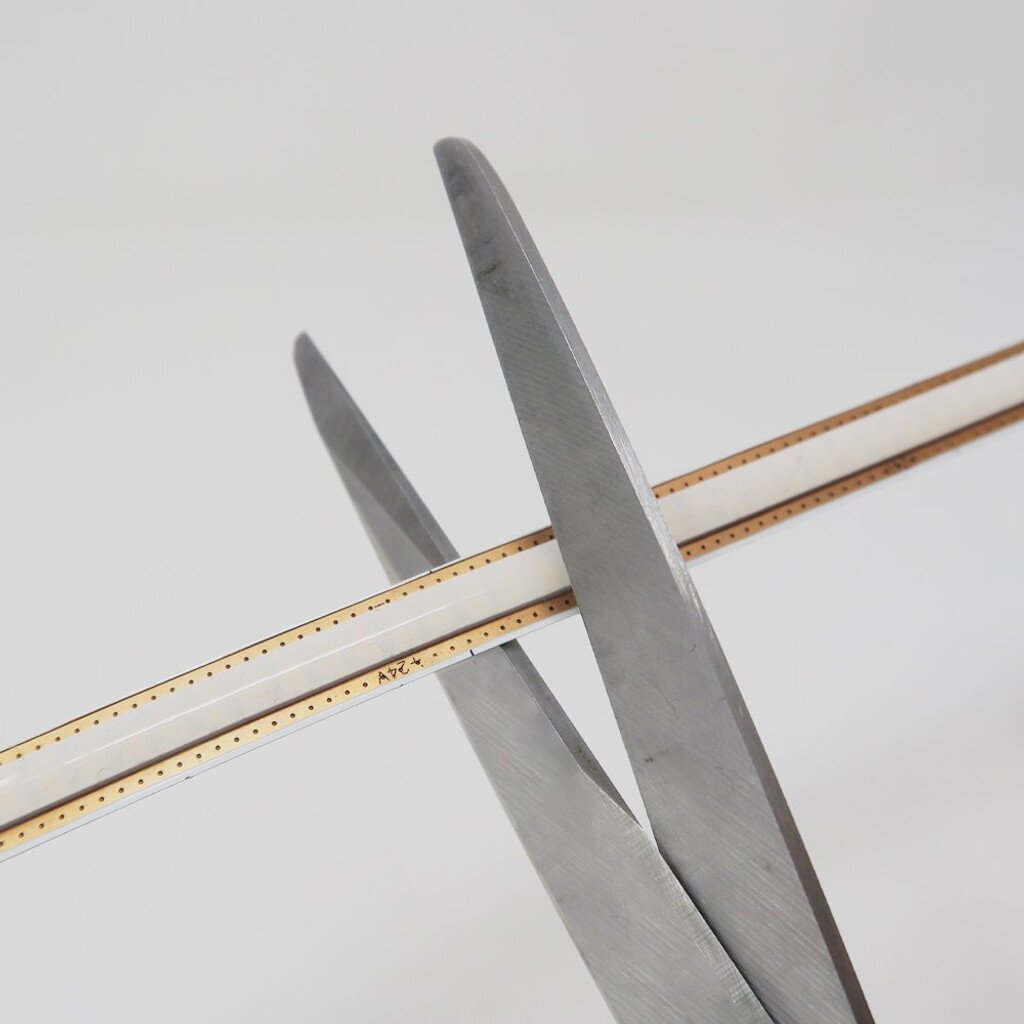

LED strip lights come with clearly marked cut points - usually indicated by copper dots or printed lines.

Knowing where to cut LED light strips is important, as these markings show exactly where it’s safe to trim using a pair of scissors. While the cut points vary between products, they are typically spaced between 15mm and 100mm apart.

Once cut, LEDs can be reconnected to a power supply to restore functionality. This can be achieved by either soldering the connections or using a solderless LED strip connector, like the Tagra Tape to Wire Connector.

A Step-By-Step Guide On How To Cut LED Strip Lights

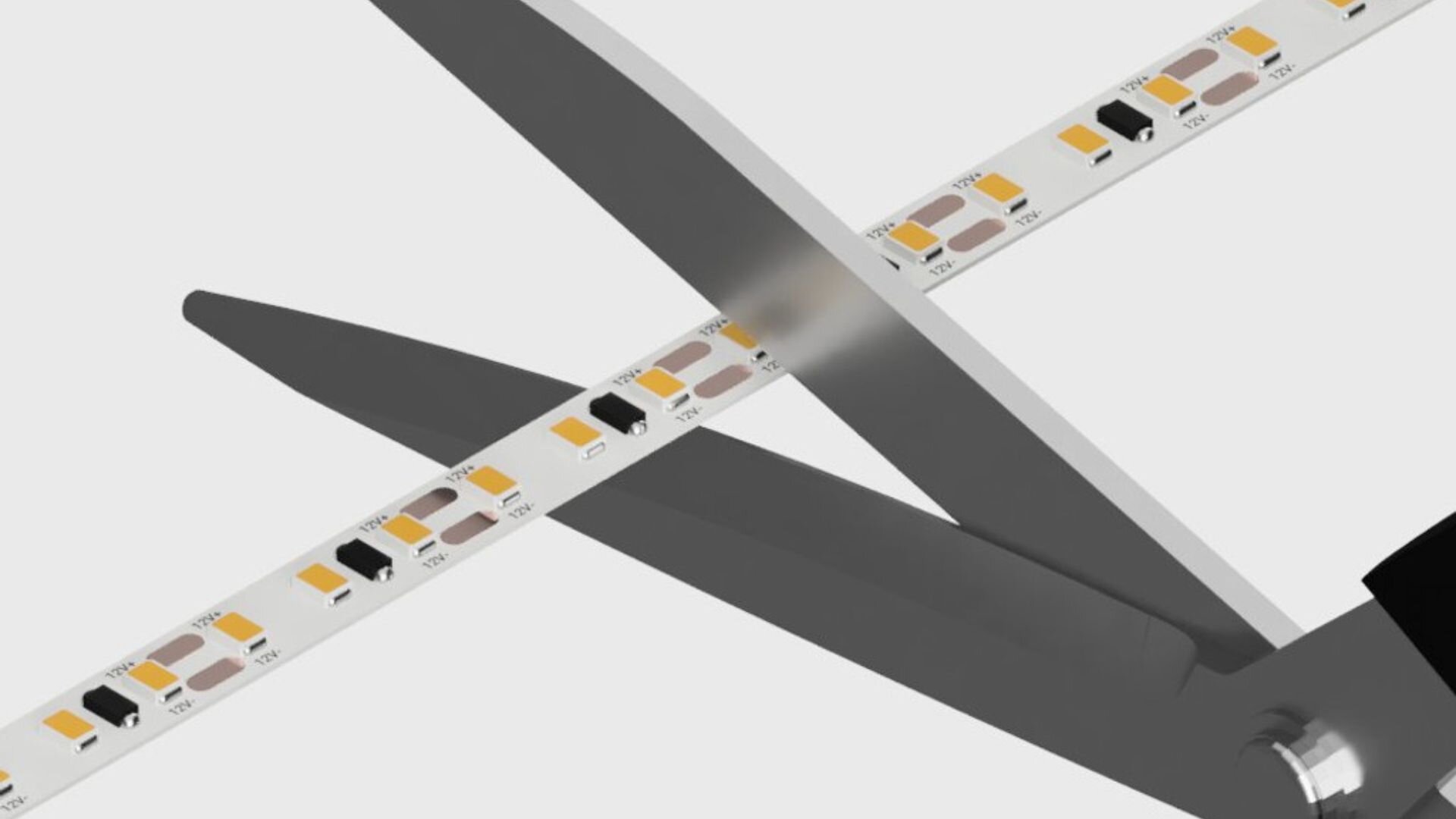

LED strip lights are best cut with a pair of sharp scissors. To cut the strips correctly, follow these steps:

1. Measure the installation area - Accurately measure the space for the LED strip installation to ensure the correct length from the outset, minimising waste and reducing the need for additional connectors.

2. Prepare the LED strip - Lay the strip flat to avoid bends or twists. Ensure the strip is straight to achieve an accurate cut.

3. Identify the cut points - Locate the designated cut points, typically marked by copper dots, a scissors icon, or small lines. Always use the cut point closest to the required length to maintain the circuits integrity.

4. Test the strip - Before making any cuts, test the LED strip to confirm that it is functioning correctly. Turn off and disconnect from power before proceeding.

5. Make a cut - Using sharp scissors, trim the strip along the marked cut points. Keep the strip taut and straight to achieve a clean, straight cut without damaging the adhesive backing or circuitry.

6. Reconnect the strip - After cutting, connect the strip to a power source. Secure the connections using solderless quick connectors or by soldering, ensuring that all contacts are secure and that every LED lights up as expected.

Cut Anywhere Lighting Solutions

For projects that require precise strip lengths, standard LED strips often come with designated cut points, which can limit flexibility.

Cut-anywhere LED solutions provide an alternative, allowing adjustments at any point along the strip to suit specific project requirements while maintaining seamless illumination.

Cut Anywhere COB LED Tape

Unlike standard LED strips with fixed cut points, Cut Anywhere COB LED tape offers unrestricted cutting along the entire strip.

This makes it particularly useful for architectural lighting, custom installations, and applications where exact lengths are essential. It ensures a continuous light output without dark spots, creating a clean, professional finish.

LED Neon Flex

For installations that require both flexibility and uniform illumination, LED Neon Flex is designed to be cut at any point while maintaining an even glow.

Its adaptable design makes it ideal for curved layouts, architectural accents, and decorative applications where precision and aesthetics matter.

How To Connect LED Strips After Cutting

After making any cuts, reconnecting the strips is the next crucial step. This is a straightforward process, though it can vary depending on the connector type.

Quick Connection Options

For a hassle-free option, solderless (clip-on) connectors offer a quick solution without the need for soldering.

1. Begin by lining up a new connector with the exposed copper pads at the end of the strip.

2. Check that the pins match the negative and positive markings on the strip, and press the connector firmly in place.

3. Test it out by giving it a gentle tug to confirm it’s secure, then turn on the power to make sure all the LEDs light up properly.

4. Finish the installation by securing any loose cables and double-checking that connectors are well sealed to protect against dust or moisture ingress.

Permanent Connection Options

For a strong and lasting connection, soldering is recommended. This technique provides the most reliable and long-lasting connections for LED strip installations.

For a detailed step-by-step guide to permanent connection options, see our comprehensive guide here.

Watch our video below to learn how to cut LED strip lights correctly for a seamless installation.

FAQs

What if I cut the LED strips in the wrong place?

Cutting outside the marked areas will break the circuit and leave part of the LED strip dark. In most cases, trimming the strip back to the nearest designated cut point will resolve the issue.

Can you cut LED strip lights with regular scissors?

Yes, as long as they’re sharp. Make sure to use a specialist neon-cutting tool when cutting neon LEDs. Never use a knife to cut neon or tape.

Can you cut LED strip lights to any length?

No, strip lights can’t be cut to any length unless using specific products, like Tagra’s Professional Cut Anywhere COB strip light.

For more information about our range of LED strip lights or our cut-to-size LED strip light service, reach out to us today. Our friendly team is happy to assist with any questions or queries.

Choose The Right Solution For Your Next Project

Find LED strips with flexible cutting options, including Cut Anywhere COB strips and Neon Flex, for a seamless, professional installation.