Trade Members Get 10% Off. Sign Up Today

What Is Neon Flex: A Comprehensive Guide

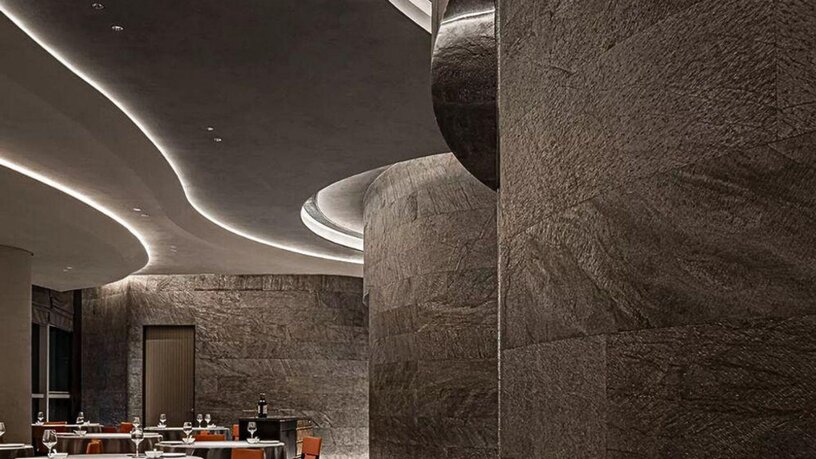

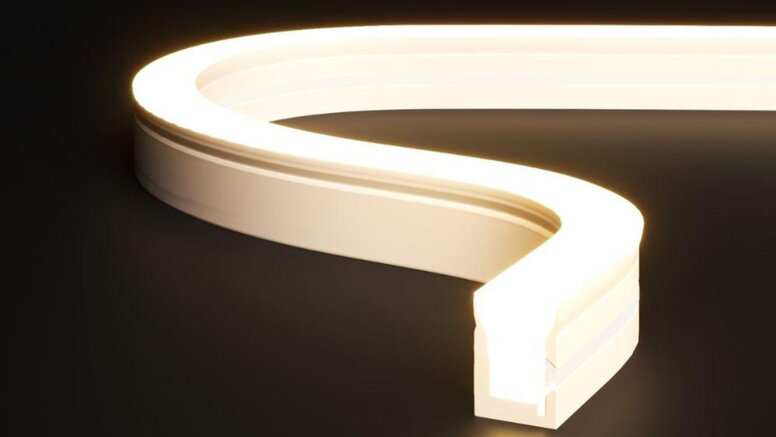

When a lighting project calls for flexibility, curvature, or seamless lines of output, LED Neon Flex is the perfect solution.

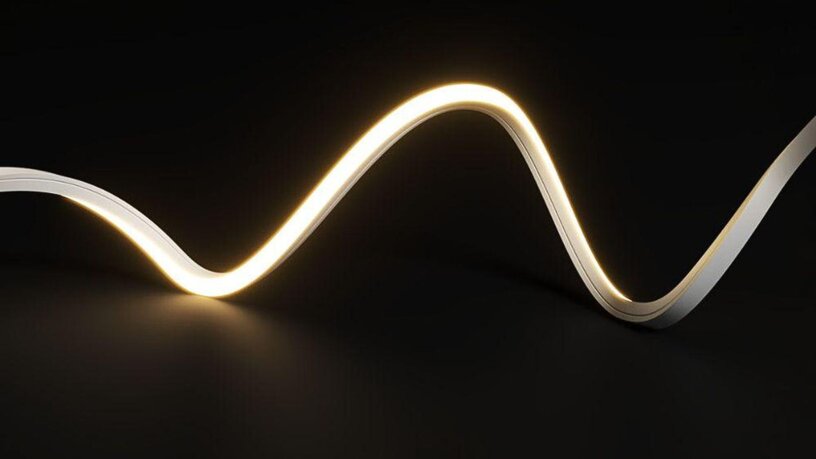

LED Neon Flex is a flexible, durable lighting system that produces a smooth, continuous line of light without deadspots or visible LED dots. It’s safer, easier to install, and highly customisable for architectural, commercial, and joinery applications.

In this guide, we’ll explain what LED Neon Flex is, how it works, and how to choose the right format for your project. It covers the full Ultra LEDs range, from compact joinery formats to architectural-grade systems for large-scale façades.

What Is Neon Flex?

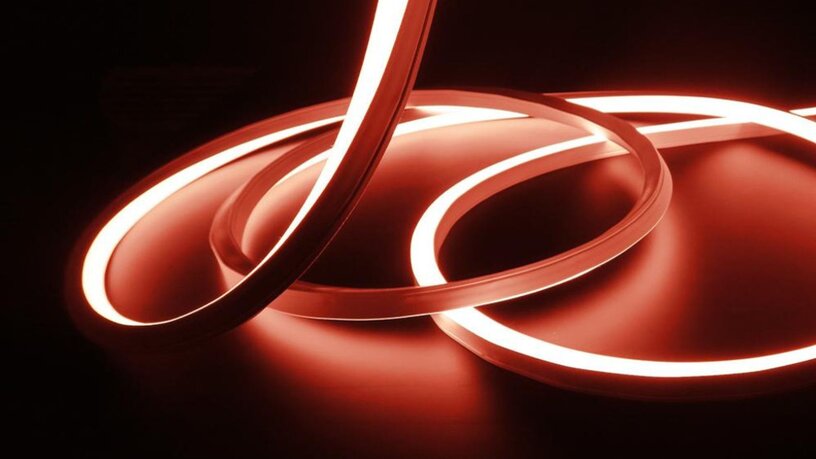

LED Neon Flex is a sealed, flexible lighting system that mimics the look of classic neon — but uses energy-efficient LED technology and a diffused silicone body for consistent light output. It produces a uniform glow across its entire surface, with no visible dots or glare.

Unlike standard LED strip lights, Neon Flex is fully enclosed in a bendable, weather-resistant jacket. This makes it suitable for shaped layouts and exposed locations where specified, offering a cleaner finish for visible installs compared to traditional LED tape. Certain ranges, such as Joinery and Quick Connect, are intended for internal or short-term use.

Neon Flex installs cleanly along curves, corners and shaped surfaces, delivering a professional finish without the need for separate profiles or diffusers.

Its sealed construction supports use in both interior and exterior settings (where rated), making it suitable for commercial, retail, hospitality, and residential lighting projects.

Why Use Neon LED Lighting?

LED Neon Flex is ideal when you need:

- Smooth, spotless lighting across curves, angles, or long runs

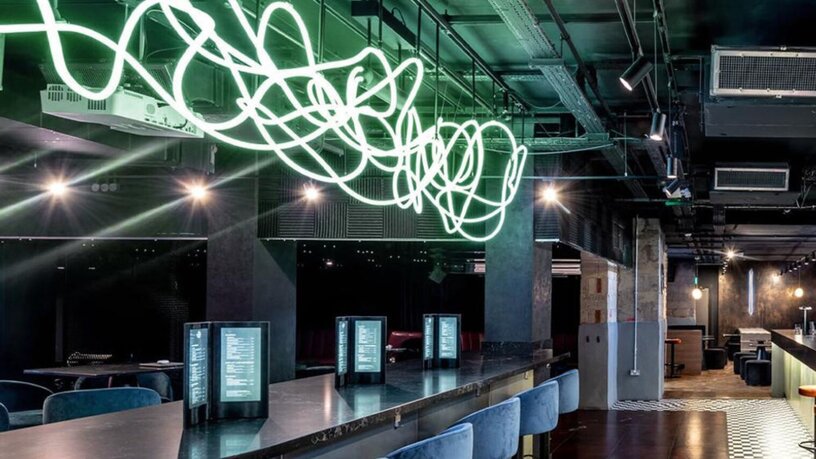

- Shaped or sculpted designs (letters, loops, outlines)

- Outdoor or harsh environments, with sealed IP-rated construction

- A clean, professional finish, without profiles or diffusers

How Does Neon Flex Work?

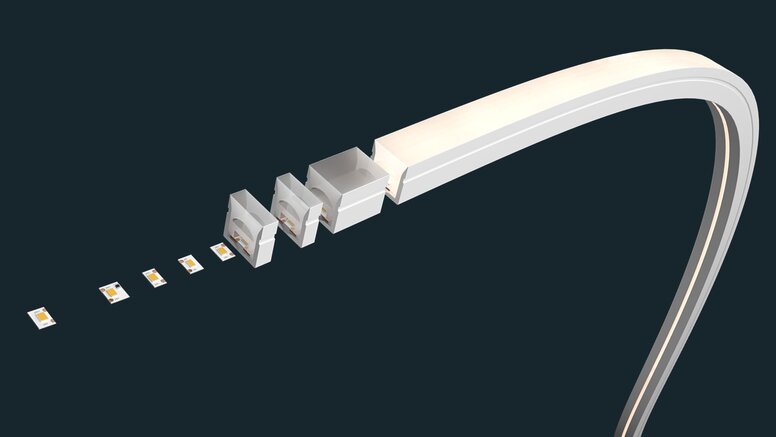

LED Neon Flex consists of:

- Internal LED strip. This provides the light source and sits within the body of the product.

- Silicone or polyurethane jacket. This outer layer diffuses the light and provides physical protection.

- Flexible circuit structure. This allows the product to bend and hold shape across curved or shaped surfaces.

Choosing Neon Flex For Your Project

LED Neon Flex products vary by bend direction, dimensions, and electrical capacity. The correct flex for your project will depend on layout complexity, lighting visibility, and environmental exposure.

Key Considerations:

- Bend direction affects shaping.

- Size affects light output, field of view, and minimum installation depth..

- IP rating determines where the product can be safely installed.

- Voltage and power feed impact maximum run length and brightness uniformity.

Bending Direction

Choosing the right bend direction is essential for clean installation. Each type is designed to flex in a specific orientation:

Bends side-to-side when laid flat.

Ideal for lettering, signage, and surface-mounted outlines.

Bends up/down when mounted upright.

Used for wrapping columns or navigating wall-to-ceiling transitions.

Perfect for installations needing both bend directions while maintaining identical size and light output, ideal for complex shapes or restricted-space applications.

Note: Always match the bend type to the intended layout. Forcing the product to bend against its designed axis may damage internal components.

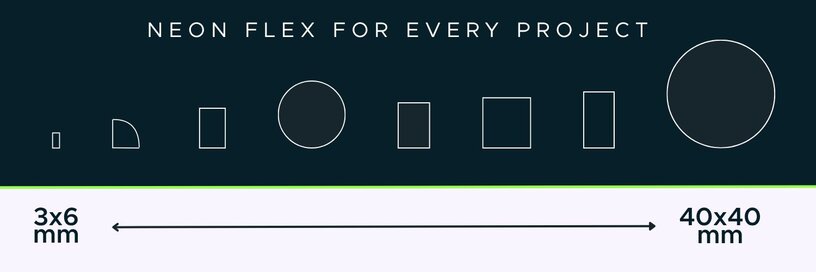

Neon Flex Size & Shape

Choose a Neon Flex size based on the light-emitting surface area, mounting method, and space availability. Common formats include:

- Miniature (3×6 mm to 6×12 mm): For joinery, recessed channels, and shallow details

- Standard (10×10 mm to 16×16 mm): For surface runs, signage, and architectural lines

- Large format (20×20 mm and above): For feature lighting, façades, and exterior structures

- Circular cross-sections: Used in decorative or suspended applications where visible light from all angles is required

Always check product dimensions against available space, bend direction, and fixing tolerances before specification

Neon Flex is available in different shapes:

- Flat Neon: Clean and modern, ideal for edge lighting and surface mounting

- Domed Neon: Softer glow, more visible from wider angles, great for decorative features or ambient accents

- Circular Neon: Visible from all directions, used in suspended loops, decorative outlines, and sculptural lighting features

Always consider not just where the light goes but how it will look from the viewer’s perspective.

Power & Run Length

Most LED Neon Flex runs on 24V DC, with 48V options available for extended continuous runs.

Always check:

-

Maximum run length per power feed

-

Voltage compatibility

-

Driver wattage (with at least 10% headroom, factoring in voltage drop and real power draw)

Adequate headroom helps maintain brightness consistency and reduce the impact of voltage drop.

Example: 14.4W/m × 6m = 86.4W. Add 10% headroom = minimum 95W driver.

Weather Protection

For outdoor use or exposure to dust, moisture, or physical contact, select an appropriate IP rating:

| IP Rating | Protection Level |

|---|---|

| IP68 | Submersiable, marine use, or permanent moisture/humidity |

| IP67 | Fully waterproof for exposed installs. |

| IP65 | Rain/Splash zones, general outdoor use. |

| Lower Ratings | Indoor use. |

Brightness & Colour

Select brightness and colour based on the lighting function and visibility requirements.

Low to mid-output applications (typically 200–600 lm/m):

Use the Joinery Series (e.g. 3×6 mm, 4×10 mm) or Décor Series (e.g. 25×25 mm) for accent lighting, shallow detailing, furniture integration, or decorative outlines

Mid-output linear runs (typically 500–900 lm/m):

The Pro Series and Build Series provide consistent output for coving, display shelving, ceiling slots, and controlled RGB/RGBW, Single Colour, or tunable white effects.

High-output exterior or feature lighting (up to 1300 lm/m):

Use the Architectural Series (e.g. 22×22 mm or larger) for extended runs, exposed installations, or IP-rated applications requiring higher lumen output and directional coverage.

Check the specified lumen output, LED density, and power draw for each model when defining installation scope or lighting intent.

Choosing Between Neon Flex and LED Tape

Use Neon Flex when:

-

The illuminated surface will be visible or shaped

-

A sealed, IP-rated product is required

-

A clean, uniform light line is critical

-

RGB or dynamic lighting is visible to the viewer

Use LED Tape when:

-

The lighting is concealed or mounted inside a profile

-

Space is limited or the profile has a shallow channel

-

Fine control is required over beam angle or optical output

-

Tight bend radii or short segment control is needed

Note: Both products can be used together for mixed-purpose applications. For example, Neon Flex may form visible perimeter lines, while LED tape is used for concealed accent or task lighting within the same install.

Our Neon Flex Series

Ultra LEDs offers six Neon Flex series, each defined by its intended application. Series differ by IP rating, light output, size profile, and bend direction options, with flexible build tolerances across the range.

Selection should be based on use case, such as location, mounting constraints, visual exposure, or shaping needs.

To explore each series in more detail, check out our Neon Flex Series Guide.

| Series Name | Designed For |

|---|---|

| Quick Connect Series | Short-term, creative installations. |

| Pro Series | Core lighting solution for everyday performance. |

| Joinery Series | Compact formats for furniture, shelving, and discrete joinery details. (Note: not all versions are cut-anywhere.) |

| Décor Series | 360° illumination ideal for decorative feature lighting in creative and commercial settings. |

| Build Series | Engineered for permanent facades, commercial, and infastructure lighting, and demanding environments. |

| Architectural Series | From building facades to marine environments, it's engineered to perform in every environment. |

FAQs

What is the best Neon Flex for small lettering or tight detail?

The most effective Neon Flex format for small lettering or tight curves is 3×6 mm or 4×8 mm from the Joinery Series. These ultra-slim profiles are designed for compact signage, shallow channels, and intricate shape work.

Which Neon Flex types are suitable for outdoor signage installations?

For outdoor signage, the best Neon Flex options are IP67 or IP68-rated models. These provide protection from water, dust, and UV exposure, making them suitable for long-term outdoor use. Where colour consistency is critical, the new 6×12 format launching in August is recommended. Depending on installation scale and performance requirements, explore the Pro, Build, or Architectural series.

When should a mounting channel be used with Neon Flex?

Mounting channels are recommended for long runs, precise alignment, or thermal management. While mounting brackets are sufficient for most short runs, aluminium channels provide added stability and a cleaner architectural finish.

Can Neon Flex be installed on 24V lighting systems?

Most Neon Flex products are designed for 24V DC systems and can integrate directly with constant voltage drivers. Ensure power capacity includes at least 10% headroom, factoring in voltage drop and actual load. Use compatible control gear for RGB or RGBW models to ensure correct operation and colour control.

Get in touch with Ultra LEDs today

Ready to specify a Neon Flex series? Contact Ultra LEDs for technical support, compatibility advice, or tailored installation guidance.