Trade Members Get 10% Off. Sign Up Today

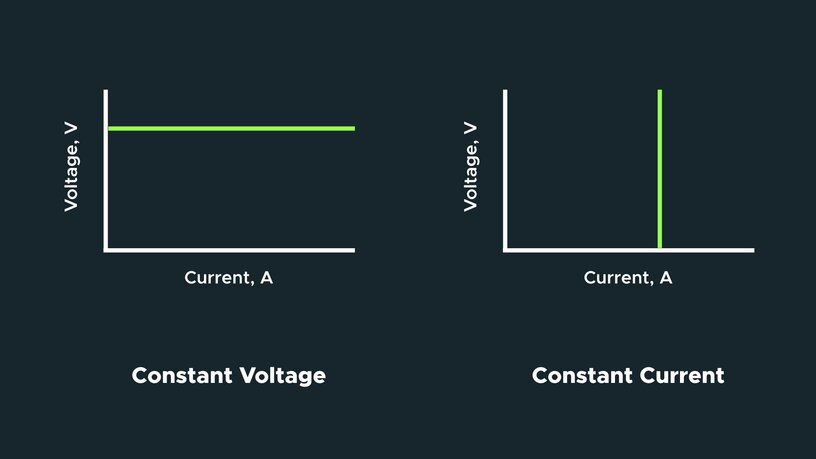

Constant Voltage vs. Constant Current LED Systems

Every LED system relies on controlled current. Whether that current is regulated at the driver or on the strip determines whether it’s a constant voltage (CV) or constant current (CC) system.

Most projects use constant voltage for flexibility and ease of specification. Constant current is used in controlled applications where brightness must remain consistent and loads are fixed.

This guide covers the technical differences between CV and CC systems, how voltage drop affects performance, and how to select the right solution for your project.

CV vs. CC: Core System Differences

All LEDs require current to operate. The difference lies in where that current is controlled:

-

Constant Voltage (CV): Current is regulated within the LED tape using resistors or integrated circuits (ICs).

-

Constant Current (CC): Current is fixed at the driver level and delivered to a matched series-connected load.

This affects wiring strategy, voltage stability, dimming compatibility, and how flexible the system is during installation.

What Is Constant Voltage (CV)?

Constant voltage systems operate at a fixed voltage, typically 12V or 24V. Current is regulated within the LED strip.

CV strips support parallel wiring and are compatible with PWM dimming, modular kits, and plug-and-play control systems. They’re used widely in architectural lighting, RGBW tape, and pixel-based installs.

Ultra LEDs' Long Run Constant Voltage COB Tape supports up to 15 metre runs from a single feed, reducing voltage drop and minimising injection requirements.

Resistors vs. ICs in Constant Voltage Tape

Constant voltage tape regulates current internally, but the method varies by product.

- Resistor-based tape is simple and cost-effective, suitable for short runs. It is more affected by voltage drop, which can lead to brightness loss at the far end of the strip.

- IC-regulated tape controls current at each segment, delivering consistent output even when voltage fluctuates.

For longer runs or installations requiring uniform brightness, IC-regulated tape provides a more stable solution and simplifies injection planning.

What Is Constant Current (CC)?

CC systems supply a fixed current from the driver, typically 350mA, 500mA, or 700mA. The LED load must be wired in series and matched to the driver’s output.

-

The total forward voltage must fall within the driver’s rated range.

-

Layouts are fixed. Any change requires rebalancing the load.

CC systems are used in:

-

Bespoke or fixed-output luminaires

-

Specialist modules with defined performance

-

Installations requiring consistent brightness or EMI-sensitive operation

They offer stability and uniformity but are not adjustable once installed. CC is best suited to projects where all parameters are defined from the outset.

Voltage Drop in Constant Voltage Systems

Voltage drop is more pronounced in CV installations, especially with long cable runs or high-power tape. Resistance in cables or PCB traces reduces voltage as distance increases, which can result in:

- Dimmer output at the far end of the strip

- Colour shift in RGB or CCT applications

- System instability if voltage falls below operating range

For a full explanation, see our Understanding Voltage Drop in LED Installations guide.

When To Use Each System

Constant voltage systems are suited to projects where flexibility, modular wiring, or system expansion is required. These include:

-

Architectural runs and RGBW or tunable white tape

-

Pixel-addressable strips and modular kits

-

Installations using plug-and-play components or PWM dimming

-

Projects where layouts may need to be adjusted on site

Constant current systems are used where specifications are fixed from the outset and performance needs to be tightly controlled. These include:

-

Bespoke luminaires and specialist LED modules

-

Narrow-beam optics or uniform linear output

-

Environments requiring stable, consistent brightness across all fittings

FAQs – What Professionals Ask

Is constant voltage better than constant current?

It depends on the application. CV is more flexible. CC is more exact and suited to fixed specifications.

Why does voltage drop matter in CV systems?

It causes reduced brightness at the end of long runs. IC-regulated tape helps stabilise output.

Can I mix a constant current driver with constant voltage tape?

No — always match the driver to the tape specification to avoid damaging components.

Get in touch with UltraLEDs today

Need support choosing between constant voltage and constant current for your next installation? Ultra LEDs supplies the LED strips, drivers, and control systems needed to deliver reliable performance in both flexible and fixed-output systems.