Trade Members Get 10% Off. Sign Up Today

A Comprehensive Guide To Pixel LEDs

When a project calls for more than static colour or uniform fades, pixel LED systems deliver motion, chase effects, and responsive control.

They control individual or grouped LEDs to enable mapped animations, real-time effects, and coordinated lighting sequences across complex installations.

This guide explains how pixel LED tape works, the difference between SPI and DMX control, and what to consider when specifying, installing, or programming a pixel system.

What Is Pixel LED Tape?

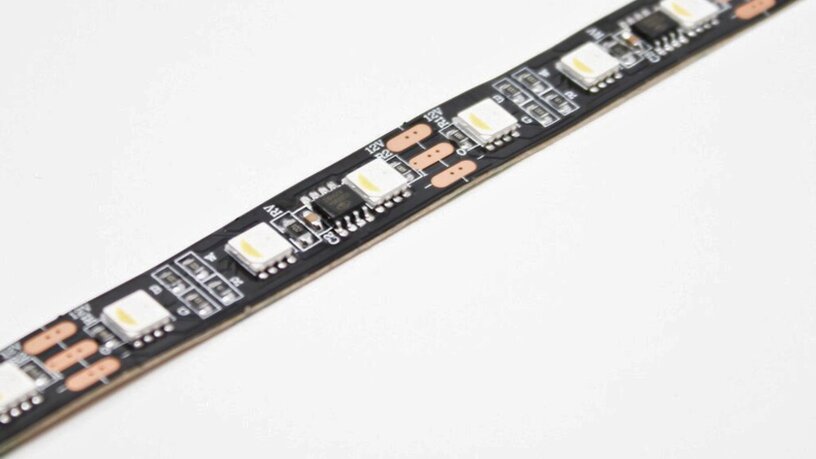

Pixel LED tape contains individually addressable LEDs, each controlled by an onboard integrated circuit (IC). These ICs don’t store data, but respond to digital signals sent by an external controller, managing colour, intensity, and timing per LED or grouped node.

A "pixel" refers to an LED (or group) with its own IC. While often called "programmable tape," pixel tape does not run logic independently. It relies on the controller to deliver real-time effects, colour shifts, or animations.

Compared to standard RGB/RGBW strips that respond uniformly, pixel systems enable node-level effects such as gradients, chase patterns, and mapped animations across a continuous run.

SPI Vs DMX Control Protocols

Pixel systems use either SPI (Serial Peripheral Interface) or DMX protocols.

-

DMX assigns fixed addresses to each pixel via software, offering direct control and high compatibility with AV systems. It suits larger, structured installations with known channel assignments.

-

SPI transfers data sequentially through each IC. It supports high refresh rates and intricate effects but may require signal repeaters over longer distances.

DMX is scalable and precise, while SPI offers faster animation and smoother pixel transitions. The right choice depends on system complexity, latency tolerance, and required visual effects.

Where Are Pixel LED Systems Used

Pixel LED systems are specified across a wide range of commercial and experiential environments where responsive, dynamic lighting enhances both function and engagement.

-

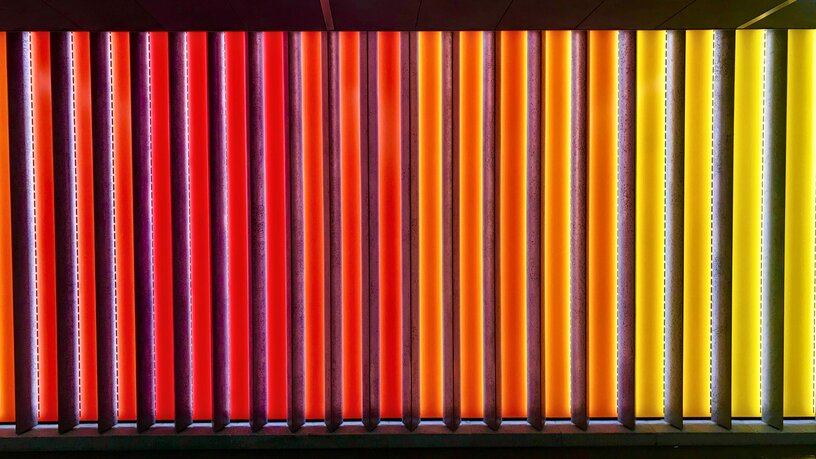

Entertainment venues – used for dynamic effects during performances, with pixel mapping supporting stage transitions and ambient immersion.

-

Retail environments – highlight merchandising zones, trigger light-based cues during product interactions, and integrate with brand-led colour palettes.

-

Museums and themed attractions – deliver synchronised lighting scenes that support storytelling, timed sequences, or reactive exhibit lighting.

-

Professional AV and broadcast – pixel systems sync with video and audio playback, offering frame-accurate lighting control for live and recorded content.

-

Hospitality interiors – adjust tone and colour temperature throughout the day or create event-based transitions without the need for manual control.

-

Commercial and architectural installations – enable façade lighting, feature wall animations, or interactive public installations controlled via sensors or building management systems.

Pixel systems are also widely used in installations requiring lighting that adapts to motion, environmental inputs, or live programming through DMX, ArtNet, or sACN control.

Controller Note: Controllers such as the Advatek PixLite A4-S support multi-universe control for mapped pixel layouts. While they do not directly process audio, they can integrate with external show control or lighting software for beat-synchronised visuals.

Products For Pixel Lighting Systems

Pixel-ready LED tape – RGB and RGBW strips with onboard ICs for per-node addressability

-

Advatek PixLite controllers – built for mapped layouts, high pixel count control, and multi-universe output

-

Standalone pixel controllers – for small-scale animations and plug-and-play effects

-

DMX-to-pixel decoders – ideal for grouped control; limited to 128 RGBW pixels per universe

-

Mean Well power supplies – reliable PSU options for pixel systems with stable voltage output

-

SPI signal boosters – support data stability across long cable runs

-

Aluminium profiles and diffusers – aid in thermal dissipation and deliver a clean architectural finish

Installation Considerations

Correct specification and preparation are critical to the long-term success of any pixel LED system. The following areas should be considered during system design:

Power Planning

Power injection is required for runs over 5 m or when voltage drops occur. Load planning should account for cable gauge, controller output, and injection spacing.

Signal Management

Signal integrity degrades with length, especially in SPI systems. Repeaters or differential receivers should be used where signal loss is expected. Cables should be twisted pair or screened, and routed away from high-voltage lines. Ground continuity between controller and tape is essential.

Since many SPI chipsets do not use a separate clock line, data lines must be clean and interference-free to maintain animation stability.

Address Mapping

Accurate planning of pixel counts, universe assignments, and output distribution is key. Channel overlaps or addressing errors can cause unpredictable behaviour. Use layout diagrams and detailed documentation to streamline commissioning and future service.

Tools like Advatek Assistant can simplify address configuration but rely on accurate system mapping.

Environmental Rating

Proper protection for pixel lighting installations depends on the environment in which they’re installed. While IP ratings provide a baseline, full weatherproofing requires assessing every component in the system — including connectors, controllers, enclosures, and power supplies.

For outdoor or high-humidity environments, options like silicone-coated LED tape, sealed profiles, and weatherproof connectors help minimise moisture ingress and environmental damage. Over time, UV exposure, thermal cycling, and water ingress can degrade silicone coatings, adhesives, and housings — shortening system lifespan if left unprotected.

Selecting the correct ingress protection level and verifying the long-term durability of materials used across the system is key to maintaining performance under continuous exposure.

For more detail, take a look at our comprehensive IP rating guide.

Mounting Options

Good thermal management is key to ensuring long-term system reliability. High-quality aluminium profiles should be selected to provide support, help with effective heat dissipation (particularly for high-density pixel installations), and deliver a neat, professional finish. The shape and positioning of the profile also influence light output - for example, angled or corner-mounted profiles can help achieve indirect wash effects.

Cable routing should be secure and hidden where possible, minimising risks of signal disruption or mechanical strain. Mounting strategies should also allow for modular access to tapes and controllers for any future servicing or upgrades.

Programming And Control

LED pixel tape can be customised and fully programmed to display a host of colours, patterns and effects. An addressable LED controller is essential to control addressable LED lighting. These controllers send signals to the individual LEDs, allowing for control over their colour, brightness, and effects.

Most setups fall into one of three categories: pre-programmed systems that run stored effects from onboard libraries; systems triggered by external events such as motion detection or scheduled timers; or fully responsive configurations using DMX, ArtNet, or sACN protocols for live, real-time control during performances and events.

Controller Options

Advatek PixLite controllers are designed for complex, mapped installations requiring high pixel counts and low-latency output. They are compatible with multiple control protocols and offer integrated universe mapping.

DMX decoders are more suitable for systems that do not require pixel-level control. These are often used in simpler installations such as static scenes, slower transitions, or when controlling grouped zones.

Software And Show Integration:

Setup typically starts with address configuration using tools like Advatek Assistant. Once assigned, playback is handled by DMX consoles or media servers that manage animation data, timing, and mapping.

All visual effects — including gradients, colour waves, and reactive transitions — are defined in the control software. The LED strip simply executes the assigned data in sequence. Multiple zones can run independently or synchronised as part of a broader installation plan.

Pixel Tape LED Case Studies

NERF Action Xperience, Manchester

Ultra LEDs worked with Technically Creative to create a fully interactive gaming environment using addressable LED strips controlled via Advatek hardware.

Tape was mounted within a custom ceiling grid, and dynamic effects adapt in real time to gameplay triggers — delivering both visual feedback and atmospheric enhancement across zones.

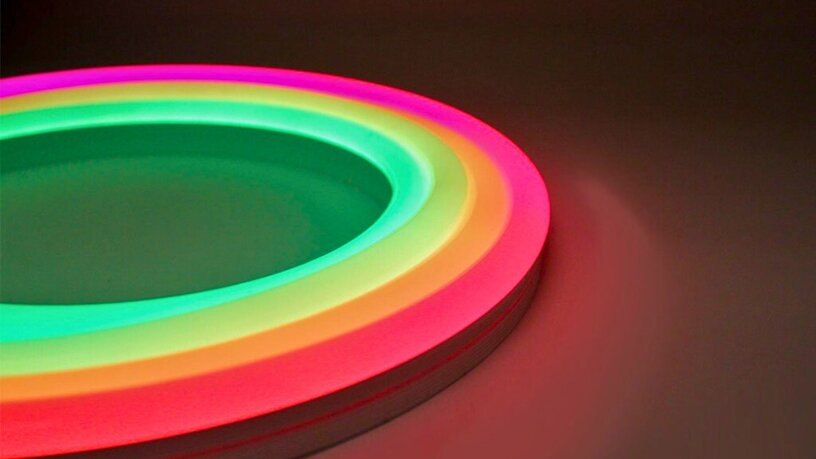

Harrow Place Arches, London

Pixel-mapped neon flex was used to light five outdoor LED arches installed in a public-facing tunnel. IP68-rated tape with injection-moulded ends ensured long-term resistance to moisture and pollution.

Advatek AS4 drivers enabled synchronised animation via an Ethernet-based daisy-chain layout. This installation demonstrated pixel lighting’s viability in architectural and urban environments.

Outcome And Benefits Of Pixel LED Systems

Implementing pixel LED systems enables control of individual LEDs or groups from a single controller, without the need for multiple daisy-chained DMX decoders.

Complex effects — such as animated sequences, gradients, and responsive colour changes — can run continuously across long strips, allowing for seamless transitions and mapped lighting without breaking the run into separate control zones.

Interactive or sensor-triggered systems also require less backend hardware, as many effects can be managed in real time via software, reducing the need for additional infrastructure.

FAQs

What’s the difference between RGB and pixel RGB?

Standard RGB LED tape displays the same colour across all LEDs at once. Pixel RGB tape contains addressable ICs, allowing each LED or LED group to be controlled independently. This enables mapped animations, chase effects, and dynamic sequences using SPI or DMX control.

How far can I run pixel tape before signal loss?

In SPI-controlled systems, signal loss typically begins after 5–10 m depending on the chipset, cable quality, and installation method. Signal repeaters or split outputs from the controller help maintain data integrity across longer runs.

When do I need power injection?

Power injection is required when the tape length exceeds 5 m or the current draw goes beyond the capacity of the power supply. Injection points ensure consistent voltage and brightness throughout the run.

Can I use DMX for pixel LED strip lights?

Yes, DMX can control pixel tape when paired with compatible decoders. However, DMX is best suited for controlling larger blocks or simpler effects due to its address limitations. For detailed control of individual pixels or mapped animations, SPI output offers greater flexibility and responsiveness.

WS2811 pixel systems are compatible with both DMX and SPI, but SPI generally provides smoother animation control at node level.

Do I need a controller or decoder for every strip?

No, but it depends on the controller. Some pixel controllers can manage multiple strips or universes, provided pixel counts and power loads stay within capacity. Others may only support a single output. Additional controllers are required when these hardware limits are exceeded.

Ultra LEDs stock all the key components for pixel lighting installations, including pixel tape LEDs, LED pixel tubes, controllers and decoders, and a range of LED accessories.

Whether it's for a small-scale setup or a large installation, our expert technical team is available to provide support at every stage, ensuring everything runs smoothly and meets project specifications.

Contact Ultra LEDs today to explore the wide range of pixel lighting components available.

Get in touch with UltraLEDs today

From compact feature lighting to large-scale mapped installations, pixel systems offer control, flexibility, and seamless integration. Ultra LEDs supplies the components, guidance, and support needed to deliver reliable, addressable lighting across any project.